Add: C3 Building, Yabian Industrial Park, Shajing Street, Baoan District, Shenzhen, China

Tel: 86-136-99856040

Tel: 86-180-26686040

Fax: 86-755-26231618

Web: www.newlytrend.com

Email: info@newlytrend.com

Which kind of plastics do you need?

The selection of a plastic material for a specific application can be a difficult task. After careful consideration, the possibilities should be narrowed down.

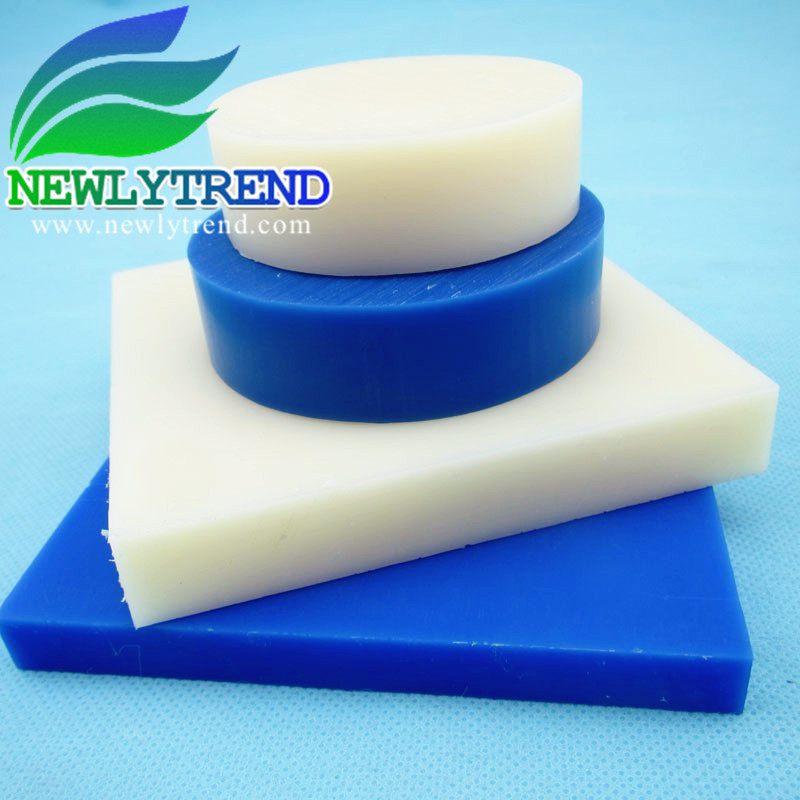

The first vital step in selecting a plastic material from the extensive range of available materials at Newlytrend Company Plastics (i.e., POM/delrin, polypropylene, ABS, acrylic, polycarbonate, nylon, PVC, etc.) is to carefully define the requirements of the application, the physical properties required and the environment in which the material will need to perform.

The following list of questions should be used to identify the application as completely as possible. In many cases, the answers to these criteria may be helpful to eliminate a particular type of plastic or an entire variety of plastics. The better the application is defined, the more chance of selecting the best material for the job.

I. Physical & Mechanical Considerations

1. What are the overall parts dimensions (diameter, length, width, thickness)?

2. What load will the part have to carry?

3. Will the design carry high loads?

4. What will the highest load be?

5. What is the maximum stress on the part?

6. What kind of stress is it (tensile, flexural, etc.)?

7. How long will the load be applied?

8. Will the load be continuous or intermittent?

9. Does the part have to retain its dimensional shape?

10. What is the projected life of the part or design?

II. Thermal Considerations

1. What temperatures will the part see and for how long?

2. What is the maximum temperature the material must sustain?

3. What is the minimum temperature the material will sustain?

4. How long will the material be at these temperatures?

5. Will the material have to withstand impact at the low temperature?

6. What kind of dimensional stability is required (is thermal expansion and contraction an issue)?

III. Chemical Considerations

1. Will the material be exposed to chemicals or moisture?

2. Will the material be exposed to normal relative humidity?

3. Will the material be submerged in water? If so, at what temperature?

4. Will the material be exposed to steam?

5. Will the material be painted? If so, what kind of paint?

6. Will the material be glued? If so, what kind of adhesive will be used?

7. Will the material be submerged or wiped with solvents or other chemicals? If so, which ones?

8. Will the material be exposed to chemical or solvent vapors? If so, which ones?

9. Will the material be exposed to other materials that can outgas or leach detrimental materials, such as plasticizers or petroleum-based chemicals?

IV. Bearing and Wear Considerations

1. Will the material be used as a bearing? Will it need to resist wear?

2. Will the material be expected to perform as a bearing? If so, what will the load, shaft diameter, shaft material, shaft finish, and rpm be?

3. What wear or abrasion condition will the material see? Note: Materials filled with friction reducers (such as PTFE, molybdenum disulfide, or graphite) generally exhibit less wear in rubbing applications.

V. Other Miscellaneous Considerations

1. Will the part have to meet any regulatory requirements?

2. Is a Flame retardant rating required? What level?

3. Should the material have a special color and/or appearance?

3-1). Natural | White | Black | Other Colors

3-2). Color match to another part or material?

3-3). Window-Clear | Transparent | Translucent | Opaque

3-4). Smooth | Polished | Textured | One-Side or Both

4. Will the part be used outdoors?

5. Is UV Resistance needed?

6. Is static dissipation or conductivity important?

6-1). Insulator | Static Dissipative | Conductive

After answering the above list of above questions, please contact Newlytrend Company for further assistance. Our sales or engineering staff will be happy to help you choose one or more available plastic materials that will meet your requirements. We stock almost all of the materials we sell, so we can provide samples or small pieces for your evaluation.