Add: C3 Building, Yabian Industrial Park, Shajing Street, Baoan District, Shenzhen, China

Tel: 86-136-99856040

Tel: 86-180-26686040

Fax: 86-755-26231618

Web: www.newlytrend.com

Email: info@newlytrend.com

How Extruded Engineering Plastic Sheet and Rod Being Made?

There is a lot of talk about extrusion on the internet, many half experts sharing their full experience about this topic. But if you are working with or want some authentic information about extrusion then welcome to the right place. Now let’s jump to our main topic for which you are here, “How Extruded Engineering Plastic Sheet and Rod Being Made?”

In very simple words, extrusion is the process of transforming raw thermoplastic polymer into some useful or usable shape, or in other words adding some utility to it. The shape and form can be of sheet, rod, pipe, profile or anything as per the industrial requirements.

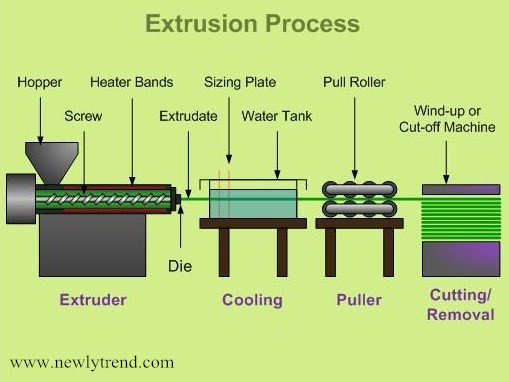

The process is also very simple and divided into few stages. At first, plastic extruder is heated to melt the solid polymer so that it can be pumped and filled into a die where it takes its final and desired shape. The plasticized polymer then sets and retains the shape after being cooled. This is not the only job of extruder, in many situations extruder is also used to mix various ingredients like colors, fibers, mineral fillers, processing aids with molten polymer. Another job which it performs is that it disperse and distribute all constituents of the mixture evenly and adequately to provide with consistent mixture, pressure and temperature.

Talking in general, an extrusion system has the following main components:

There are various types and sizes of extruders are available which you can choose according to your needs and job requirements. The size of barrel is determined by the diameter of barrel or screw or by the barrel length-to-diameter ratio. Normally it ranges from 0.5 inch to 10 inch or 15 to 250 mm or in latter case 24 L/D. We hope this piece of information would be helpful in understanding the plastic extrusion process.

Relative Topic: What are Engineering Plastics?

Engineering Plastics: POM Sheet/Delrin Sheet, POM Rod/Delrin Rod, Nylon Sheet, Nylon Rod, PP Sheet, PP Rod, ABS Sheet and so on.