Add: C3 Building, Yabian Industrial Park, Shajing Street, Baoan District, Shenzhen, China

Tel: 86-136-99856040

Tel: 86-180-26686040

Fax: 86-755-26231618

Web: www.newlytrend.com

Email: info@newlytrend.com

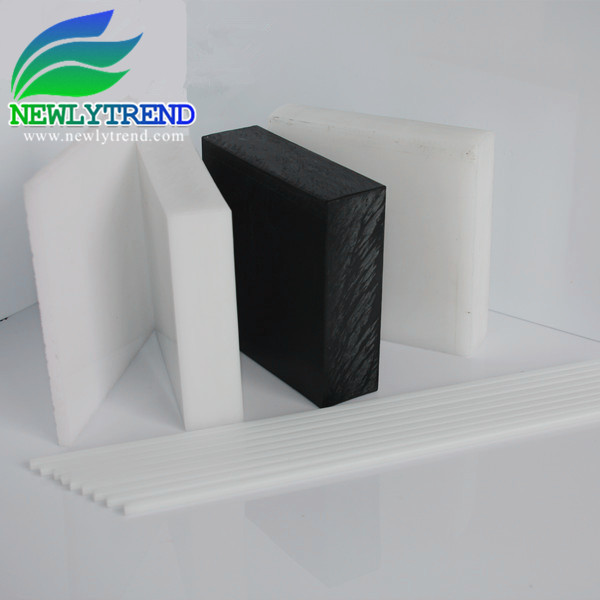

Polyoxymethylene (POM), also known as acetal, polyacetal and polyformaldehyde, is an engineering thermoplastic used in precision parts requiring high stiffness, low friction and excellent dimensional stability. As with many other synthetic polymers, it is produced by different chemical firms with slightly different formulas and sold variously by such names as Delrin, Celcon, Ramtal, Duracon and Hostaform.

Typical applications for injection-molded POM include high performance engineering components such as small gear wheels, ball bearings, ski bindings, fasteners, knife handles, and lock systems. The material is widely used in the automotive and consumer electronics industry.

Polyoxymethylene was discovered by Hermann Staudinger, a German chemist who received the 1953 Nobel Prize in Chemistry. He had studied the polymerization and structure of POM in the 1920s while researching macromolecules, which he characterized as polymers. Due to problems with thermal stability, POM was not commercialized at that time.

Around 1952 research chemists at DuPont synthesized a version of POM, and in 1956 the company filed for patent protection of the homopolymer. DuPont credits R. N. MacDonald as the inventor of high molecular weight POM. Patents by MacDonald and coworkers describe the preparation of high molecular weight hemiacetal (~O-CH2OH) terminated POM, but these lack sufficient thermal stability to be commercially viable. The inventor of a heat-stable (and therefore useful) POM homopolymer was Dal Nagore, who discovered that reacting the hemiacetal ends with acetic anhydride converts the readily depolymerizable hemiacetal into a thermally stable, melt processable plastic.

DuPont completed construction of a plant to produce its own version of acetal resin, named Delrin at Parkersburg, West Virginia, in 1960. Also in 1960, Celanese completed its own research. Shortly thereafter, in a limited partnership with the Frankfurt firm Hoechst AG, a factory was built in Kelsterbach, Hessen; from there, Celcon was produced starting in 1962, with Hostaform joining it a year later. Both remain in production under the auspices of Celanese, and are sold as parts of a product group now called Hostaform/Celcon POM.

POM is characterized by its high strength, hardness and rigidity to −40 °C. POM is intrinsically opaque white, due to its high crystalline composition, but it is available in all colors. POM has a density of ρ = 1.420–1.440 g/cm³.

POM homopolymer is a semi-crystalline polymer (75–85% crystalline) with a melting point of 175 °C. The POM copolymer has a slightly lower melting point of 162–173 °C.

POM is a tough material with a very low coefficient of friction. However, it is susceptible to polymer degradation catalyzed by acids, which is why both polymer types are stabilized. Both homopolymer and copolymer have chain end groups (introduced via end capping) which resist depolymerization. With the copolymer, the second unit normally is a C2 (ethylene glycol) or C4 (1,4-butanediol) unit, which is introduced via its cyclic acetal (which can be made from the diol and formaldehyde) or cyclic ether (e.g. ethylene oxide). These units resist chain cleavage, because the O-linkage is now no longer an acetal group, but an ether linkage, which is stable to hydrolysis. POM is sensitive to oxidation, and an anti-oxidant is normally added to molding grades of the material.

POM advantages:

High abrasion resistance

Low coefficient of friction

High heat resistance

Good electrical and dielectric properties

Low water absorption